| APPLICATION |

| Air-arc carbon rod gouging

technology is mainly applied in the fields of metal

structure, metal casting, and shipbuilding, etc.

IT enhances processing efficiency, and improves

working condition by adopting the technique of air

arc carbon gouging instead of the old pneumatic

chiseling. The metal surface treated by carbon rod

gouging is smooth clean and flat without ant harmful

influence to the metal performance. It is featured

by convenient operation, low cost and noiselessness. |

| ATTENTION

TO THE USAGE OF AIR-ARC GOUGING |

1.Power: Normal

D.C. for welding machines can be used for air-arc

gouging carbon electrode.

2.Range of currency: The currency range adopted

directly influences the processing quality and

results. If it is too small, it will be difficult

for gouging; if too large, it will cause heated

carbon head too long, which will result in the

rod becomes thinner and the processing quality

poor. Therefore the proper currency range as shown

in the table herewith should be adopted in accordance

with the model and dimension of the gouging carbon

electrode.

3.Range of Air pressure:

The normal air pressure range is 4-6kg/cm2, which

shall be in compliance with the diameter of gouging

carbon electrode. In general, higher air pressure

is for bigger diameter of the rod and lower pressure

for smaller diameter. If air pressure is too high,

electric arc is unstable; if too low, melted metal

can not be blew off easily, which will influence

the quality of gouging groove.

|

| CARBON

ELECTRODE SIZE AND CUT PERFERMANCE |

| Width of Groove |

Rod Dia x 1.4 |

| Depth of Groove |

Rod Dia x 1.4 |

|

| CABON

ELECTRODE STATRC PERFERMANCE STANDARD |

| Electrical

Resistanec |

19 ¦Ì¦¸.m |

| Breaking Strength |

27Mpa |

| Bulk Density |

1.57g/cm3 |

| Ash Content |

0.8% |

| Water Content |

0.3% |

|

| |

|

|

| Rectangular

Copper-Coated Carbon Electrodes(D.C.) |

Jointed

Coper-Coated Carbon Electrodes(D.C.) |

|

|

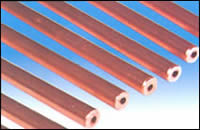

| RECTANGULAR

COPPER-COATED CARBON ELECTRODES(D.C.) |

HalfRound

Copper-Coated Carbon Electrldew(D.C.) |

|

|

| Round

Copper-Coated Carbon Electrodes(D.C.) |

Sureface of different lines Copper-Coated Carbon Electrodes(D.C.) |

| |

|

| |

|